Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$2400

≥1 Set/Sets

model numarası.: H-TC1927

Marka: KC

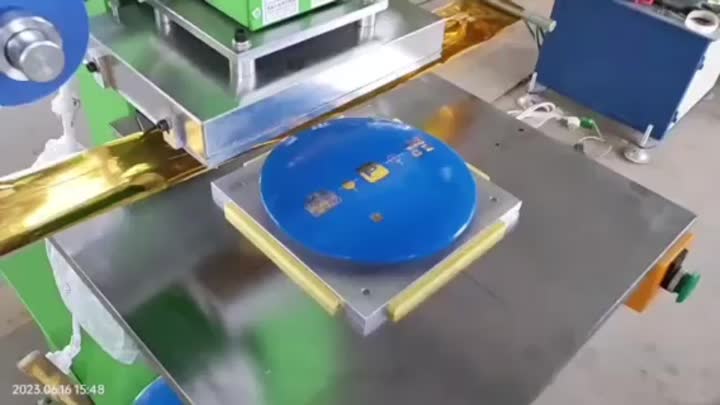

Türler: Isı Presi

Uygulanabilir Endüstri: İnşaat Malzemesi Dükkanları, Yiyecek ve İçecek Fabrikası, Restoran, Perakende, Yemek mağazası, İnşaat işleri

Garanti Dışı Servis: Video teknik desteği, Çevrimiçi destek, Yedek parçalar, Saha bakım ve onarım hizmeti

Yerel Hizmetler Nerede Sağlanmalı (hangi ülkelerde Yurtdışı Hizmet Satış Noktaları Vardır): Brezilya, Peru, Endonezya, Pakistan, Hindistan, ispanya, Malezya, Fas, Kenya, Güney Kore, Kolombiya, Romanya

Showroom Konumu (hangi ülkelerde Yurt Dışında örnek Odalar Bulunmaktadır): Mısır, Kanada, Birleşik Krallık, Amerika Birleşik Devletleri, İtalya, Vietnam, Peru, Pakistan

Statü: Yeni

Baskı Plakası Türü: GRAVÜR

Anavatan: Çin

Kullanım: Etiket yazıcısı, Bill Yazıcı

Otomasyon Derecesi: Yarı otomatik

Renk Numarası Ve Yüzey Numarası Yazdırma: Tek renk

Garanti Süresi: 1 yıl

Temel Satış Noktası: Çalıştırması Kolay

Pazarlama Türü: Sıcak Ürün 2019

Mekanik Test Raporu: Sağlanan

Video Fabrikası Denetimi: Sağlanan

Temel Bileşen Garanti Süresi: 1 yıl

Temel Bileşenler: Basınçlı kap, PLC

Damgalama Plakası Boyutu: 190*270mm

Pnömatik Sıcak Damgalama Makinesi // Kullanım ve Karakterler

Örnekler

Teknik veriler

|

Pnömatik Sıcak Damgalama Makinesi // Parametre

|

H-TC1520

|

H-TC1927

|

|

H-TC2129

|

H-TC3025

|

|

Yapı

Veri

Katalog

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.