Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$2750

≥1 Set/Sets

model numarası.: H-TC1927N

Marka: KC

Türler: Isı Presi

Uygulanabilir Endüstri: Yiyecek ve İçecek Fabrikası, Çiftlikler, Perakende, Yemek mağazası, Matbaalar, Enerji ve Madencilik, Yiyecek ve İçecek Mağazaları

Garanti Dışı Servis: Video teknik desteği, Çevrimiçi destek, Yedek parçalar, Saha bakım ve onarım hizmeti

Yerel Hizmetler Nerede Sağlanmalı (hangi ülkelerde Yurtdışı Hizmet Satış Noktaları Vardır): Arjantin, Güney Kore, Şili, BAE, Kolombiya, Cezayir, Sri Lanka, Romanya, Bangladeş

Showroom Konumu (hangi ülkelerde Yurt Dışında örnek Odalar Bulunmaktadır): BAE, Kolombiya, Cezayir, Sri Lanka, Bangladeş, Güney Afrika, Kazakistan, Ukrayna

Statü: Yeni

Baskı Plakası Türü: Tipo baskı

Anavatan: Çin

Kullanım: Kağıt Yazıcı, Etiket yazıcısı, Kart Yazıcısı, Bill Yazıcı

Otomasyon Derecesi: Yarı otomatik

Renk Numarası Ve Yüzey Numarası Yazdırma: Tek renk

Garanti Süresi: 1 yıl

Temel Satış Noktası: Yüksek doğruluk

Pazarlama Türü: Sıcak Ürün 2019

Mekanik Test Raporu: Sağlanan

Video Fabrikası Denetimi: Sağlanan

Temel Bileşen Garanti Süresi: 1 yıl

Temel Bileşenler: Basınçlı kap, Rulman

Örnekler

Makine Açıklaması

|

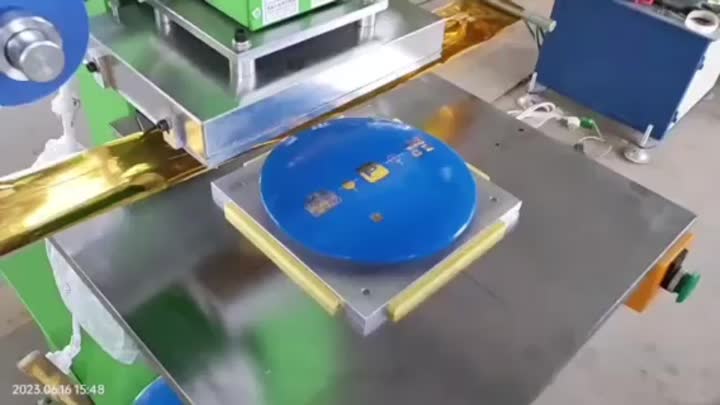

The main action of the hot stamping machine is that the hot plate moves up and down. When the hot plate touches the product or the workbench, a strong pressure is formed. For the operator, the potential risk may cause personal injury. The safety requirements of hot stamping machines are higher than those of pad printing machines and screen printing machines. A widely used design is to install a workbench that can automatically enter and exit the workbench. The hot stamping machine with automatic worktable entry and exit can only be regarded as a balance between safety and cost, so it is very popular among users. When users have further requirements for safety, measures such as installing safety gratings and safety covers will also be considered. |

|

|

Pneumatic movement-table hot stamping Machine //Parameter |

|

|

H-TC1520N

|

H-TC1927N

|

|

H-TC2129N

|

H-TC3025N

|

|

Pneumatic movement-table hot stamping machine //Advantage |

|

|

|

|

Katalog

Detaylar

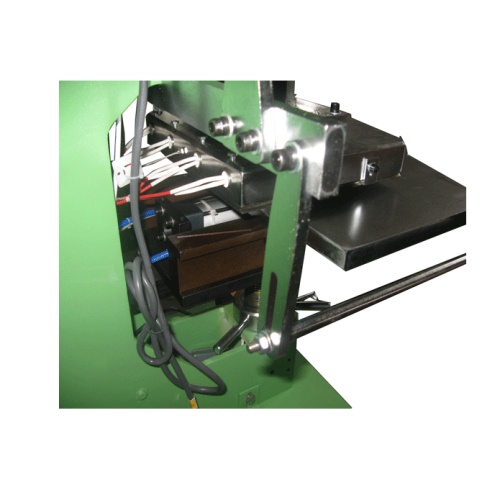

Yapı

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.