Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$4500

≥1 Others

| Model | |

| Şimdi başvurun |

model numarası.: KC

Marka: KC

Uygulanabilir Endüstri: Oteller, Konfeksiyon Mağazaları, Yiyecek ve İçecek Fabrikası, İnşaat Malzemesi Dükkanları, Matbaalar

Garanti Dışı Servis: Video teknik desteği, Saha bakım ve onarım hizmeti, Çevrimiçi destek, Yedek parçalar

Yerel Hizmetler Nerede Sağlanmalı (hangi ülkelerde Yurtdışı Hizmet Satış Noktaları Vardır): Malezya, Pakistan, Vietnam, Avustralya, Hindistan, Filipinler

Showroom Konumu (hangi ülkelerde Yurt Dışında örnek Odalar Bulunmaktadır): Cezayir, Kenya, Hindistan, Meksika, Arjantin, Sri Lanka

Video Fabrikası Denetimi: Sağlanan

Mekanik Test Raporu: Sağlanan

Pazarlama Türü: Yeni Ürün 2020

Temel Bileşen Garanti Süresi: 1 yıl

Temel Bileşenler: Motor

Statü: Yeni

Çeşitleri: Görüntü Ayarlayıcı

Otomasyon Derecesi: Yarı otomatik

Anavatan: Çin

Garanti Süresi: 1 yıl

Temel Satış Noktası: Yüksek Sertlik, Taşınabilir, Uzaktan gözlemleme

Örnekler

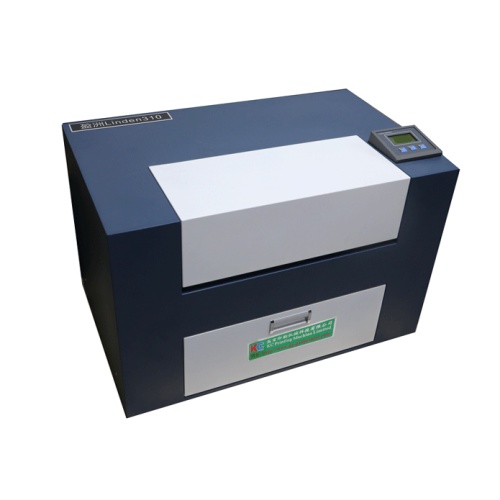

Çoğu baskı işlemi, özellikle ped baskı, ekran baskı, sıcak damgalama, flekso baskı, ofset baskı ve gravür baskı gibi özel baskı alanında baskı plakaları gerektirir. Daha yüksek teknik bariyerlere sahip bazı baskı işlemleri, Bilgisayar Doğrudan Platemating Technology'ye (CTP) doğru gelişmektedir, yani bilgisayarda depolanan tasarım taslağını bir baskı plakası oluşturmak için baskı plakasına doğrudan çıkarmak için bilgisayar kontrolünü kullanır. Ofset baskı, flekso baskı ve ekran baskısı nispeten olgundur. Daha düşük teknik bariyerlere sahip bazı baskı işlemleri hala geleneksel platemasyon sürecini takip etmektedir. İlk olarak, görüntü ve metin platemaking filmine çıktı ve daha sonra platemaking filmi baskı plakasını yapmak için baskı plakasını örtmek için kullanılır. Pad baskı, ekran baskısı ve sıcak damgalama hala bu işlemi koruyor. Platemaking filmi, bir evcil hayvan filminde ışığa duyarlı bir katmanı kaplayarak oluşturulan bir film haline gelir. Platemaking filminin şeffaf alanı ultraviyole ışığı iletecek ve şeffaf olmayan alan ışığı engelleyecektir. Tabii duyarlı katman, ultraviyole ışığı ileten alanda katılaşacak ve ışığa duyarlı katman ultraviyole ışığı iletmeyen alanda katılaşmayacak ve geliştirme ve yıkama sırasında yıkanacaktır.

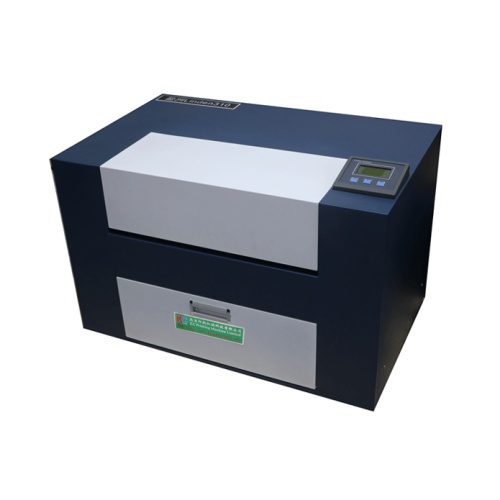

Çoğu PAD yazıcısı, ekran yazıcısı ve sıcak damgalama makinesi operatörleri, yetersiz karı olan küçük ölçekli yatırımcılardır ve pahalı lazer fototipleri satın almaya istekli olmayabilir. Bununla birlikte, KC Serisi lazer fototipleri ucuzdur, orta derecede doğruluğa sahiptir ve kullanımı kolaydır. Genellikle maliyetlerini yaklaşık üç ay içinde geri kazanırlar. Pad yazıcılar, ekran yazıcılar ve sıcak damgalama makinesi işleme işleriyle uğraşıyorsanız veya diğer baskı fabrikaları için film çıkışı ve plaka yapma işi sağlıyorsanız, KC marka lazer fototiplayı düşünebilirsiniz.

Veri Sayfaları

|

Laser film Imagine Setter //Parameter |

|

|

Technical parameters |

PM-410FL |

|

|

|

PM-510FL |

|

|

|

|

PM-610FL |

|

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Laser imagine setter //Advantage |

|

|

Function |

|

Katalog

Çözüm

|

Brefie |

|

|

Usage |

|

|

Package |

|

|

Store |

|

|

Parameter |

|

|

Advantage |

|

|

Usage |

|

|

Reminding |

|

|

Film after the formation of latent image after exposure to water after developing and fixing of water freeze treatment. Ultimately form the image area and non-image area. Usage︰ Using PM-410FL film output machine film exposed film developing and fixing processing. Production Advantage ︰ Powder Package, easily for keeping;

Developer can prepare them by themselves can also buy ready-made packaging development powder. Developing powder is extremely easy to use package, usage is simple, become suitable for a small amount of flushing Gan Guangpian or print and images. 6) "Snapshot: that is to restore the silver film on the silver does not dissolve in order to prevent further exposure of this part of silver halide film image. Fixing time for hand-punching is no photographic film after partially transparent, plus double the time. Storage︰ Developer and fixation easy long-term exposure to air oxidation, should be installed in the brown bottle Gaiyan, placed in the shade, avoid sun exposure. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.