Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$22500

≥1 Set/Sets

| Model | |

| Şimdi başvurun |

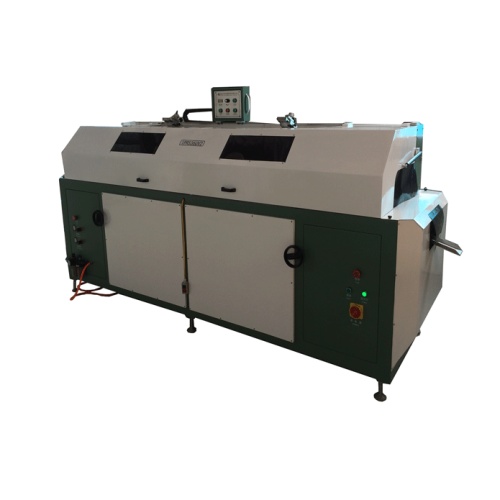

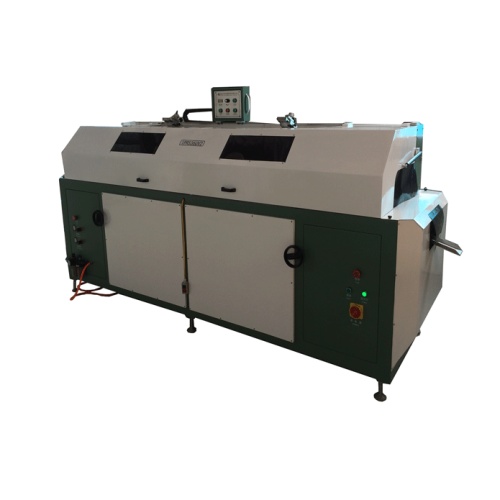

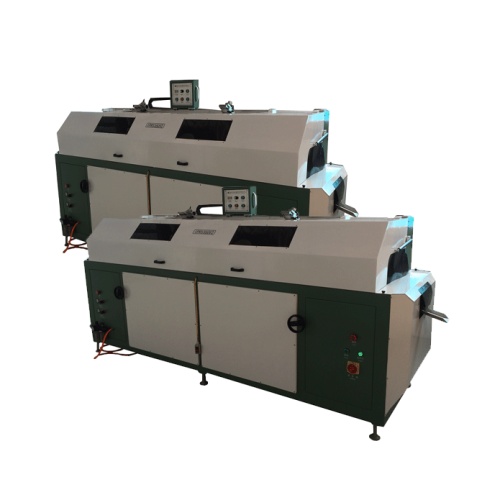

model numarası.: SZD-202C

Marka: KC

Baskı Plakası Türü: Ekran yazıcısı

Uygulanabilir Endüstri: Yiyecek ve İçecek Fabrikası, Yemek mağazası, Yiyecek ve İçecek Mağazaları, İnşaat Malzemesi Dükkanları, Matbaalar

Garanti Dışı Servis: Video teknik desteği, Saha bakım ve onarım hizmeti, Çevrimiçi destek, Yedek parçalar

Yerel Hizmetler Nerede Sağlanmalı (hangi ülkelerde Yurtdışı Hizmet Satış Noktaları Vardır): Malezya, Pakistan, Vietnam, Türkiye

Showroom Konumu (hangi ülkelerde Yurt Dışında örnek Odalar Bulunmaktadır): Endonezya, Almanya, Kanada, Fas, Kolombiya

Statü: Yeni

Anavatan: Çin

Kullanım: Tüp Yazıcı

Otomasyon Derecesi: Otomatik

Renk Numarası Ve Yüzey Numarası Yazdırma: İki renk

Garanti Süresi: 1 yıl

Temel Satış Noktası: Yüksek doğruluk

Pazarlama Türü: Sıcak Ürün 2019

Mekanik Test Raporu: Sağlanan

Video Fabrikası Denetimi: Sağlanan

Temel Bileşen Garanti Süresi: 1 yıl

Temel Bileşenler: Rulman

Tip: Otomatik ekran baskı makinesi

Stil: Ekran süreci baskı baskısı

Renk Ve Sayfa: Tek renkli baskı pres

| Introduce |

|

Automatic two-color no fixed point bottle silk screen machine / / technical parameter |

|

Automatic two-color no fixed point bottle silk screen machine / / advantage |

|

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.