Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

$84000

≥1 Set/Sets

| Model | |

| Şimdi başvurun |

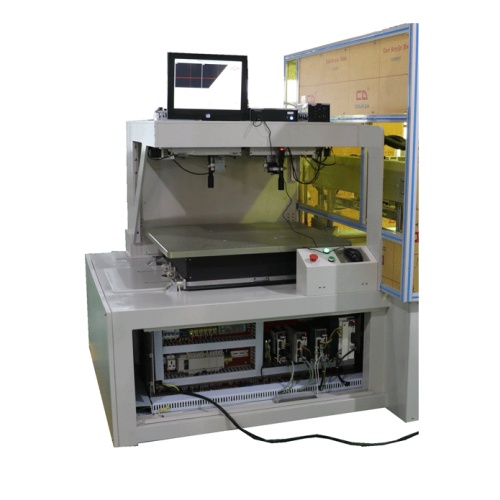

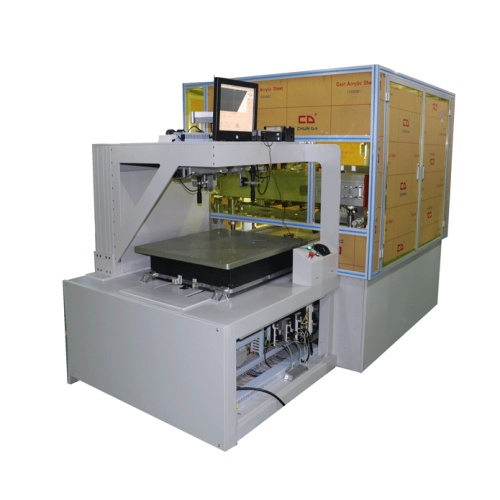

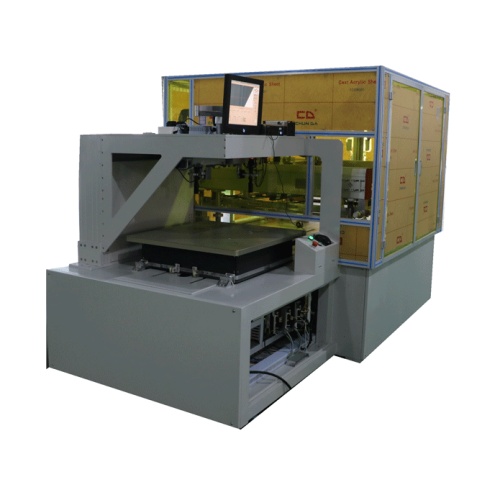

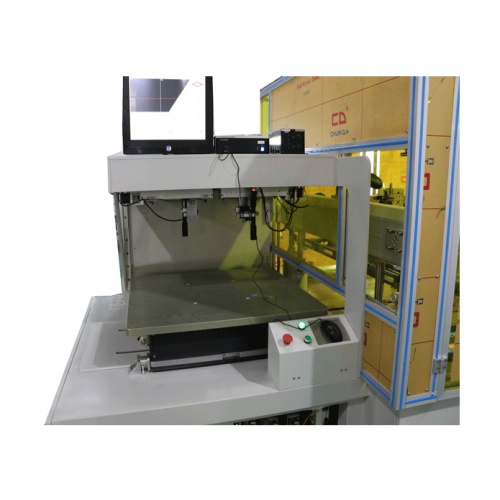

model numarası.: IP6070S

Marka: KC

Baskı Plakası Türü: Ekran yazıcısı

Uygulanabilir Endüstri: Yiyecek ve İçecek Fabrikası, Yemek mağazası, Matbaalar, Çiftlikler, İnşaat işleri

Garanti Dışı Servis: Video teknik desteği, Saha bakım ve onarım hizmeti, Çevrimiçi destek, Yedek parçalar

Yerel Hizmetler Nerede Sağlanmalı (hangi ülkelerde Yurtdışı Hizmet Satış Noktaları Vardır): Endonezya, Japonya, Şili, BAE, Malezya, Pakistan, Vietnam

Showroom Konumu (hangi ülkelerde Yurt Dışında örnek Odalar Bulunmaktadır): Endonezya, Tayland, BAE, Kolombiya, Fas, Pakistan

Statü: Yeni

Anavatan: Çin

Kullanım: Kağıt Yazıcı

Otomasyon Derecesi: Yarı otomatik

Renk Numarası Ve Yüzey Numarası Yazdırma: Tek renk

Garanti Süresi: 1 yıl

Temel Satış Noktası: Çalıştırması Kolay, Otomatik

Pazarlama Türü: Sıcak Ürün 2019

Video Fabrikası Denetimi: Sağlanan

Temel Bileşen Garanti Süresi: 1 yıl

Temel Bileşenler: Rulman

Tip: Dikey ekran baskı makinesi

Stil: Ekran süreci baskı baskısı

Yapı: PREST PRESS

Renk Ve Sayfa: Tek renkli baskı pres

Başvuru: Ambalaj baskısı

Hareketler: Ekran tabağının aşağı

Basılacak: Düz Nesneler

Squegee Inme: Sınırlı anahtarı ayarlayın

Squeeee Ve Ekran Plakası Kontrolü: Yüksek hassasiyetli doğrusal kılavuz

Çalışma Masası: Vakum Çalışma Tablosu

Konumlandırma Sistemi: Industries Computer + Windows Servo

| Technical parameter |

|

CCD positioning precision screen printer //Guide |

| Suitable for high-precision center-positioning printing of flat / hard plate-shaped printing pieces of screen printing operations, such as cold plate / film (EL), LCD panel, diffuser, cell phone Cover Lens, silicon solar cells, precision passive components and other printing processes, computers, TV windows, etc. Artificial products to be printed on the (set in advance as the area set in advance) printing stage, the camera began to scan the default production The outer edge of the product, the platen runs on a predetermined track, when running to coincide with the stored data, the platen automatically runs to To be printed area, down to the printing frame after the screen printing, after the completion of the frame and the nose up, printing station moved to the loading area, people Workers take the product, so a cycle of action is completed; you can proceed to the next cycle of action. |

| Positioning Slide Table |

|

| Printing device: |

| Pneumatic knife back to the knife lifting device; Print travel Panasonic servo motor with linear guide, printing stroke accurate. |

| Control System: |

| LED coaxial light CCD camera image taken 14-inch TFT screen display alignment system; 14-inch color man-machine interface, fast memory and read, print quality data management; Visual alignment system using industrial computer + windows high-level program-driven three-axis servo alignment system, automatic alignment, fast and accurate; Stepper motor drive automatically shift, quickly capture product images, to achieve precise positioning. |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.